Collection: Molten glass on wood

Discover our stunning collection of handcrafted molten glass on wood home decor. Each piece is handmade by artisans using natural materials like recycled glass, tree roots, and driftwood collected from beaches.

We offer unique glass decoration pieces including glass serving bowls, candle holders, jugs, fish bowls and flower vases that add an earthy elegance to any space.

The melted molten glass seamlessly flows over the organic wood shapes, creating a molten glass on wood fusion that highlights the rustic textures of nature. An eco-friendly way to bring the beauty of the outdoors into your home.

Shop our driftwood glass bowl and molten glass on driftwood decor collection today for sustainable, one-of-a-kind accent pieces.

-

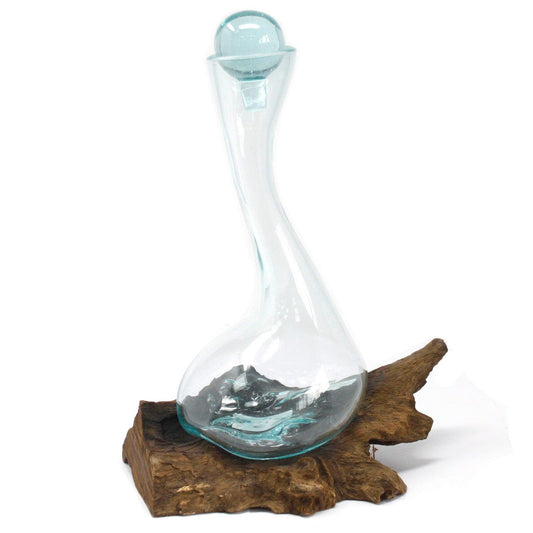

Molton Glass V-shaped Art Vase on Wood

Regular price £52.00Regular priceUnit price / per£52.00Sale price £52.00Sold out -

Molten Glass Large Fish Tank 3.7 litre (with light cavity)- 30cm

Regular price £49.50Regular priceUnit price / per£49.50Sale price £49.50 -

Molten Coloured Glass on Wood - Small Bowl

Regular price £19.50Regular priceUnit price / per£19.50Sale price £19.50 -

Molten Crackled Glass Tank on Wood

Regular price £30.75Regular priceUnit price / per -

Large Molten Glass Vase - Terrarium Jar on Wood

Regular price £41.40Regular priceUnit price / per -

Molten Glass Arfully Misshapen Bowl on Wood

Regular price £21.45Regular priceUnit price / per -

Molten Glass Small Flower Vase and Tealight Holder on Wood

Regular price £25.20Regular priceUnit price / per -

Sold out

Sold outSmall Molten Glass on Root Wood

Regular price £38.95Regular priceUnit price / per£29.95Sale price £38.95Sold out -

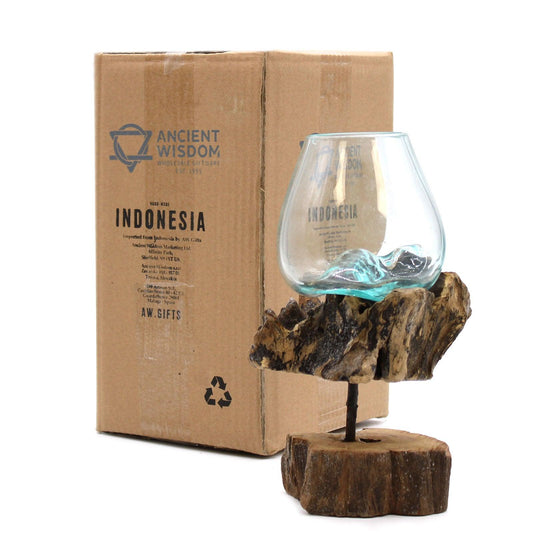

Large Molten Glass on Root Wood Stand

Regular price £40.95Regular priceUnit price / per£30.95Sale price £40.95Sold out -

Extra Large Molten Glass Bowl on Root Wood Stand

Regular price £50.95Regular priceUnit price / per£37.95Sale price £50.95Sold out -

Molten Glass Bowl on Rare Parasite Wood

Regular price £28.95Regular priceUnit price / per£28.95Sale price £28.95 -

Molten Glass Illuminated Large Fish Tank 3.7ltr

Regular price £41.95Regular priceUnit price / per£59.95Sale price £41.95Sold out -

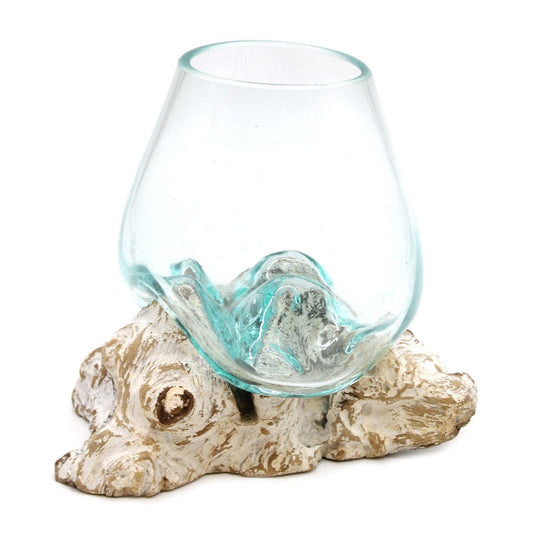

Molten Glass on Whitewash Wood - Medium Bowl

Regular price £23.95Regular priceUnit price / per£23.95Sale price £23.95 -

Recycled Beer Bottles - Beer Glass on Wood

Regular price £18.95Regular priceUnit price / per£18.95Sale price £18.95 -

Recycled Beer Bottles - Mini Flower Vase on Wood

Regular price £15.95Regular priceUnit price / per£15.95Sale price £15.95 -

Recycled Beer Bottles - Flower Vase on Wood

Regular price £24.95Regular priceUnit price / per£24.95Sale price £24.95 -

Recycled Beer Bottles - Large Fancy Sweet Bowl on Wood

Regular price £34.95Regular priceUnit price / per£34.95Sale price £34.95 -

Recycled Beer Bottles - Square Bowl on Wood

Regular price £32.95Regular priceUnit price / per£32.95Sale price £32.95 -

Recycled Beer Bottles - Lrg Wide Bowl on Wood

Regular price £34.95Regular priceUnit price / per£34.95Sale price £34.95 -

Recycled Beer Bottles - Wide Bowl on Wood

Regular price £28.95Regular priceUnit price / per£28.95Sale price £28.95 -

Recycled Beer Bottles - Small Bowl on Wood

Regular price £22.95Regular priceUnit price / per£22.95Sale price £22.95 -

Carved Hand with Molten Glass Bowl

Regular price £41.95Regular priceUnit price / per£41.95Sale price £41.95 -

Molten Glass Tank on Wood with Stand - Small Bowl

Regular price £23.95Regular priceUnit price / per£23.95Sale price £23.95 -

Molten Glass on Wood with Stand - Large Bowl

Regular price £33.95Regular priceUnit price / per£33.95Sale price £33.95Sold out -

Molten Glass on Wood with Stand - Medium Bowl

Regular price £29.95Regular priceUnit price / per£29.95Sale price £29.95Sold out -

Molten Glass on Whitewash Wood - Vase - Medium

Regular price £34.95Regular priceUnit price / per£34.95Sale price £34.95 -

Molten Glass on Whitewash Wood - Vase - Small

Regular price £27.95Regular priceUnit price / per£27.95Sale price £27.95 -

Molten Glass on Whitewash Wood - Large Bowl

Regular price £33.95Regular priceUnit price / per£33.95Sale price £33.95 -

Molten Glass on Whitewash Wood - Small Bowl

Regular price £16.95Regular priceUnit price / per£16.95Sale price £16.95 -

Molten Glass Tank on Wood with Stand - Medium Bowl

Regular price £28.95Regular priceUnit price / per£28.95Sale price £28.95 -

Sold out

Sold outMolten Glass on Wood - Candle Holder

Regular price £24.95Regular priceUnit price / per£24.95Sale price £24.95Sold out -

Molten Glass on Wood - Water Jug

Regular price £30.95Regular priceUnit price / per£30.95Sale price £30.95 -

Molten Glass on Wood Whisky Set

Regular price £48.95Regular priceUnit price / per£48.95Sale price £48.95 -

Molten Glass on Wood Wine Decanter

Regular price £34.95Regular priceUnit price / per£34.95Sale price £34.95 -

Molten Glass on Wood - Open Lrg Bowl

Regular price £41.95Regular priceUnit price / per£41.95Sale price £41.95 -

Molten Glass on Wood - Hanging Bowl

Regular price £43.95Regular priceUnit price / per£43.95Sale price £43.95

Molten glass on wood

Melted Glass Ornaments FAQs

What is molten glass?

Molten glass is glass that has been heated to a high temperature so that it turns into a liquid state and becomes workable.

- The most common types of glass that are melted and made molten are soda-lime glass and borosilicate glass.

- Glass becomes molten at temperatures above 1100°C or 2000°F. It needs to be kept at this high temperature while being shaped and worked into glass products.

- Molten glass is highly viscous, like thick honey. This allows it to be shaped and molded in different ways.

- When molten glass starts to cool down, it begins the process of solidifying back into a solid glass form. This needs to happen slowly and evenly to prevent cracks and breaks.

- Skilled glassmakers use tools and molds to shape the molten glass into decorative and functional items like vases, bottles, dishes, marbles, and more while it is still in the workable heated state.

- Once the molten glass cools fully, the glass product retains its hardened shape. The cooling process can take hours or days depending on the size and thickness of the glass item.

- Working with molten glass is an ancient craft that requires great care and skill to shape, mold, and cool the glass properly. It continues to be used today by glass artists and manufacturers around the world.

How do you make molten glass?

Here are the key steps for making molten glass:

- Obtain raw materials - The main ingredients are silica sand, soda ash and limestone. Other additives can be used to modify qualities like color and clarity.

- Batch mixing - The raw materials are precisely measured and mixed together into a "batch". This ensures the glass has the right chemical composition.

- Melting - The batch is loaded into a furnace and heated up. Temperatures can reach over 2500°F to melt the mixture into a molten liquid state.

- Fining - Impurities are removed from the molten glass by adding fining agents like salt and antimony oxide. This helps clarify and purify the glass.

- Conditioning - The glass is heated and cooled slightly to homogenize it and make it workable. This prepares it for shaping.

- Forming - The conditioned molten glass is gathered onto blowpipes, puntys rods or into molds to be blown, pressed, cast or drawn into desired shapes.

- Annealing - Newly formed glass objects are slowly cooled in a temperature-controlled kiln to relieve internal stresses and prevent breakage.

- Inspection - The finished annealed glass pieces are inspected for flaws and breaks. Quality checks ensure they meet specifications.

- Additional steps like grinding, cutting, decorating and packaging may be done before the glass products are ready for shipping.

So in summary, the essential steps are weighing and mixing the glass batch, melting it at extremely high temperatures to make it molten and workable, then forming it into glassware before carefully annealing the products. Skilled craftsmanship is needed throughout the process.

Home Decor Inspiration

View all-

Ultimate Guide to Creating Cosy in Your Home

Discover essential tips for creating a cosy home with our guide on colour theory, lighting, textures, and space organisation. Learn DIY projects, product recommendations, and eco-friendly practices to enhance comfort...

Ultimate Guide to Creating Cosy in Your Home

Discover essential tips for creating a cosy home with our guide on colour theory, lighting, textures, and space organisation. Learn DIY projects, product recommendations, and eco-friendly practices to enhance comfort...

-

The Best Plants for Your Bohemian Home - A Comp...

Discover the best plants for Bohemian decor, including care tips and styling ideas to create a lush, eclectic home vibe. Explore layering, natural materials, green corners, and more to enhance...

The Best Plants for Your Bohemian Home - A Comp...

Discover the best plants for Bohemian decor, including care tips and styling ideas to create a lush, eclectic home vibe. Explore layering, natural materials, green corners, and more to enhance...

-

Crafting a Bohemian Bedroom Oasis on a Budget

Embracing Bohemian Elegance Bohemian style, known for its eclectic and artistic flair, can also be a uniquely personal and cost-effective approach to bedroom design. This article explores various budget-friendly techniques...

Crafting a Bohemian Bedroom Oasis on a Budget

Embracing Bohemian Elegance Bohemian style, known for its eclectic and artistic flair, can also be a uniquely personal and cost-effective approach to bedroom design. This article explores various budget-friendly techniques...